Printer Internal Metal Bracket Support Sheet Metal Fabrication Parts

Overview Product Description Processing Stamping + bending + welding + grinding + gold plating Company Profile Our Advan

Basic Info

| Model NO. | CY-BJ-CZHD-0004 |

| Standard | GB, EN, API650, JIS Code, TEMA |

| Tolerance | +/-0.01mm |

| Surface Treatment | Electroplating |

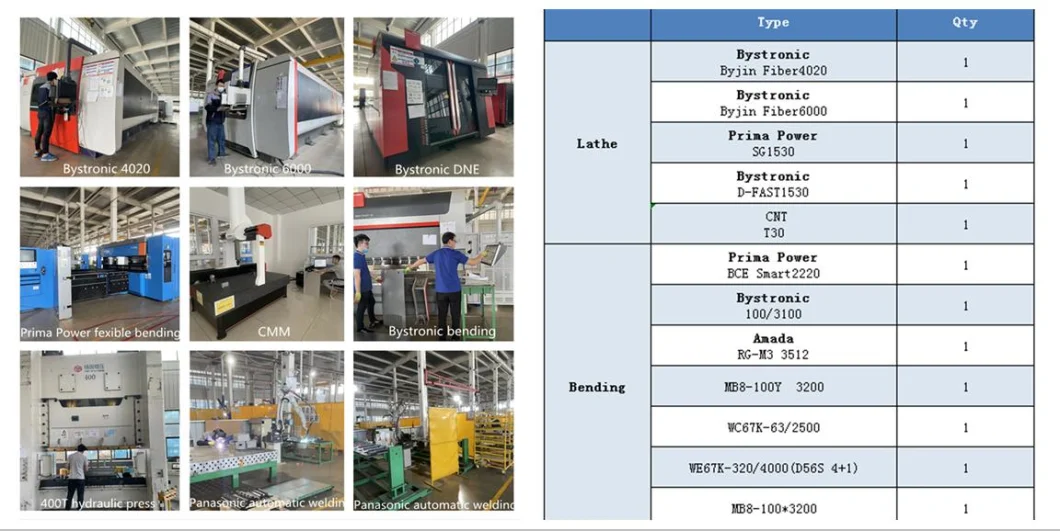

| Machining Method | Laser + Bend + Welding + Powder Spraying + Asse |

| Material | Aluminum |

| Weight | 0.5kg |

| MOQ | 20 |

| Quality Standard | ISO 9001 |

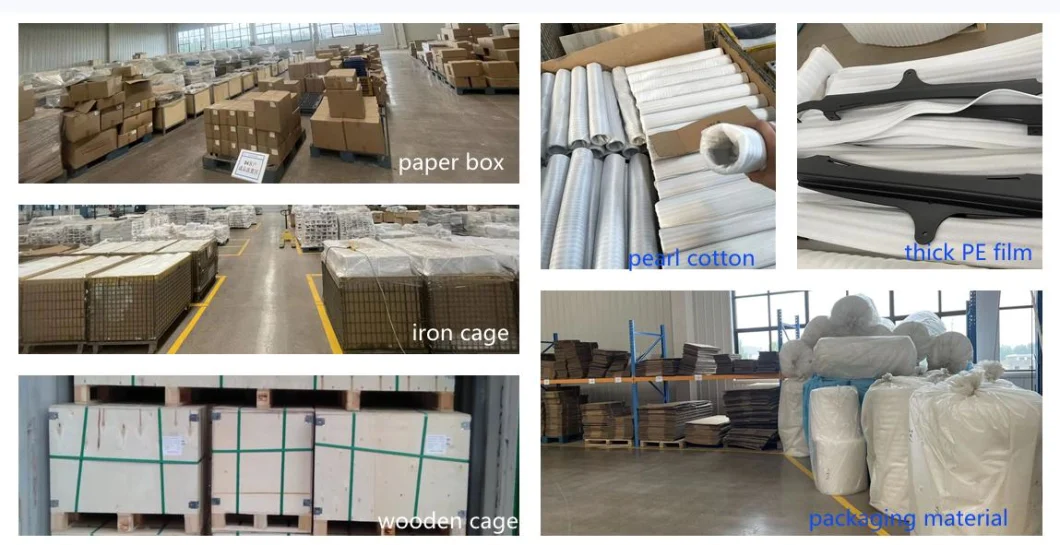

| Transport Package | According to Customer Requirements |

| Specification | 20*20 |

| Trademark | OEM |

| Origin | Qingdao, China |

| HS Code | 76061230 |

| Production Capacity | 150000 Piece/Pieces Per Month |

Product Description

Processing

Stamping + bending + welding + grinding + gold plating

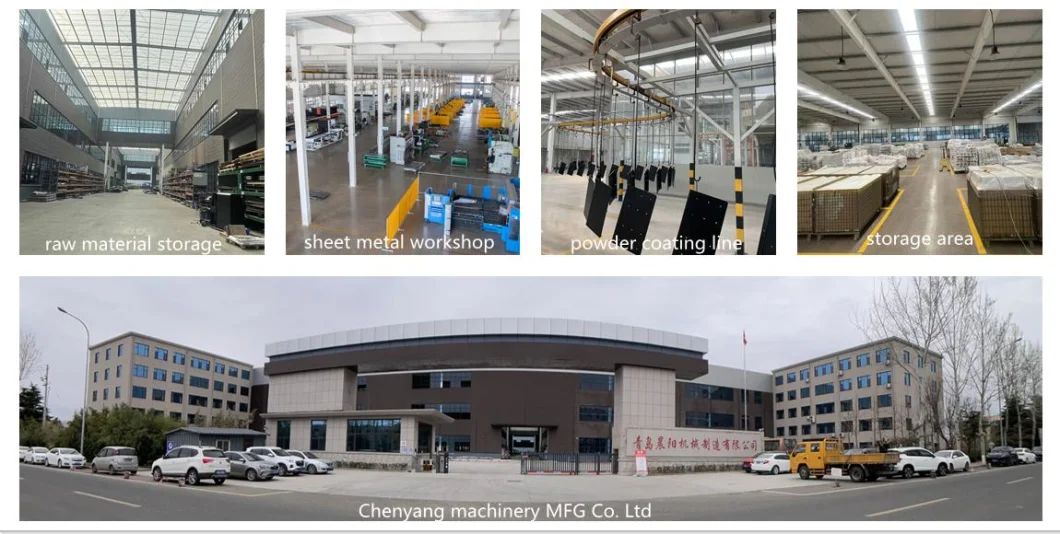

Company Profile

Our Advantages

Certifications

Packaging & Shipping

Customers

FAQ

1. Samples Leading Time ?

Mould items ( casting & injection plastic):15-20 dayssheet plate : 5 daysCNC maching : 3-5 daysWelding : 2 daysMould cost : 100% prepaid and free samples for quality confirmation ,free <usd102. Shipment terms :FOB QINGDAO /SHANGHAI /Tianjin CIF , C&F

3. Payment terms :Mini order :100% preapid if less than $3000;15 working days for delivery.Beverage bottle, cosmetic bottle, medicine bottle, jar etc.Mass Order : 30% prepaid and balance cleared before delivery or at sight of OBL ;20 -30 working days based on order quantity.

4. Whether inspection to keep the quality ?

1.Accessories Samples inspeciton;2.Finished samples inspeciton ;3.First article inspection ;4.Rounting inspeciton ;5.spot inspection ;6.100% inspection if requested .5. Any World famous customers as a quality reference ?

| 1. Railway vehicles | CRRC (China ) | 4. Heater | Media (China) |

| 2. Motocycles | Suzuki( Japan ) | 5. Generators | Digatron (Germany) |

| 3. Communication | Skyware Global (USA) | 6. Leisure Massage Couch | Earthlite (USA) |

Send to us